Pipe Jacking - Micro Tunneling

Overview

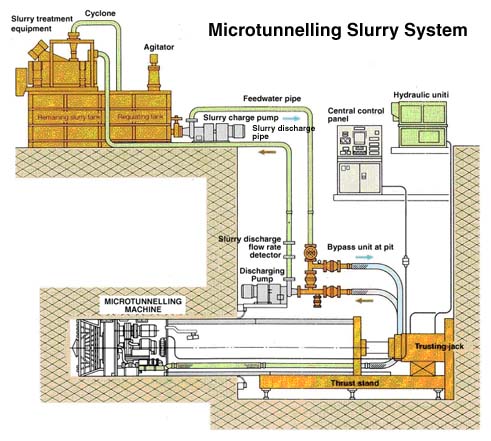

Microtunnelling is a trenchless and remotely controlled pipe jacking method that eliminates the need for worker entry into shafts or tunnels. It combines excavation, pipe jacking, and spoil removal in a seamless, automated process.

Key Applications

- Remote-Controlled Operation: Managed from a control console above ground.

- Worker Safety: No worker entry is required inside shafts or tunnels.

Simultaneous Processes: Excavation, spoil removal, and pipe jacking occur concurrently. - Minimal Surface Disruption: Only drive and reception shafts require excavation, reducing the need for open trenches.

Microtunnelling Tunnel Boring Machines (MTBM)

1. Specialized Equipment

- Microtunnelling uses electrically powered MTBMs with cutting heads.

- The MTBM is attached to the pipe being advanced as the tunnel is bored.

2. Ground Condition Adaptability

- MTBMs are designed to operate in a variety of ground conditions, including gravel, sand, silt, and clay.

- The type of cutter head and spoil removal system is selected based on predicted ground conditions.

3. Accurate Excavation

- Laser-guidance systems and computerized monitors ensure precise alignment and evenly stressed pipelines.

Advantages of Microtunnelling

- Enhanced Accuracy: Pipelines installed using microtunnelling are more precise than those laid with open trench methods.

- Improved Safety: Minimizes risks to workers by reducing the need for onsite labor in confined spaces.

- Environmentally Friendly: Reduces surface disruption and eliminates extended open trenches.

- Versatile Application: Suitable for nearly all ground conditions with customizable equipment configurations.

Our Services

experience

0

+

years as a trusted provider

COnsult Us Today!

+6019-203 7900